How do innovations affect the lugs of the hatches of factories?

2025-01-25

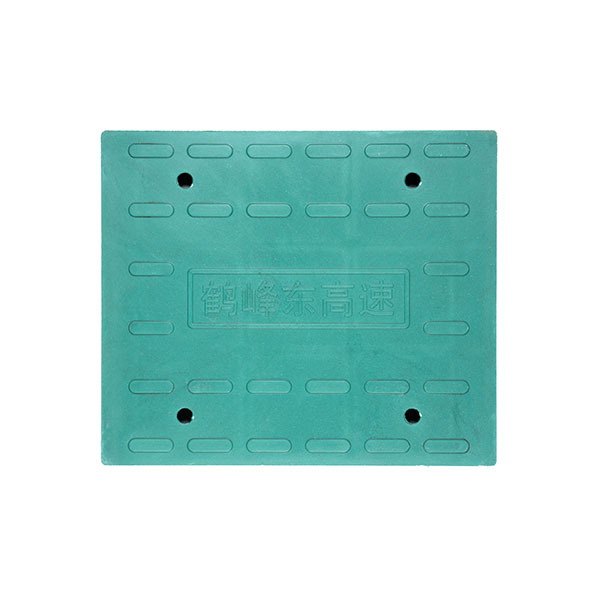

Innovation is the engine of progress, and their influence on the production of various products becomes more noticeable every day. This is especially obvious in the case of the production of urban infrastructure activities as the lids of the hatches of factories. These products play an important role in ensuring the safety of pedestrians and vehicles, as well as in protecting communal systems laid underground. In the modern world, where the requirements of the safety and durability of materials become more and more strict, factories producing hatches of hatches are striving to introduce more and more advanced technologies and innovative solutions. This allows you to improve product quality, make it more environmentally friendly and adaptive to operating conditions.

New generation materials

In recent years, the development of new materials for the production of the Luke cover has taken a significant step forward. For example, the use of composites and polymer concrete allows you to create covers that have the highest resistance to mechanical damage and adverse weather conditions. Modern materials provide not only a long service life, but also a lighter weight of products, which facilitates their transportation and installation. In addition, composites are environmentally friendly, since they are based on materials to be processed. For factories, this means reducing costs and increasing production efficiency.

Smart technologies in the production of hatches

Modern lids of the hatches of factories are equipped with smart technologies, such as pressure and temperature sensors, a system for detecting the presence of liquid and even the possibility of remote monitoring. These functions allow specialists to respond in a timely manner to the slightest signs of problems and prevent emergency situations. For example, in the case of raising the water level in the sewer system, sensors will instantly transmit information to the dispatch center. The use of such technologies significantly reduces risks for both urban infrastructure and the hatches themselves, which increases their durability and reduces the cost of repair and replacement.

Improving the design process

Modern CAD technologies allow you to develop the models of the Luke of factors, taking into account many factors and operating conditions. Virtual testing and modeling allow engineers to predict the behavior of the material under load, choose the optimal geometric parameters and thereby create a product that is most consistent with customer needs. This reduces the deadlines for the entry of new models to the market and allows you to instantly make changes to the design process. Plants using these methods significantly increase product quality, providing consumers with more reliable and durable products.

Environmental care

At the present stage of industry development, the issue of environmental friendliness of production is becoming more and more relevant. Factories engaged in the production of hatch cover are striving to minimize the harmful effects on the environment. This is expressed in the use of secondly processed materials, reducing emissions in the production and implementation of energy -efficient technologies. The declared environmental responsibility significantly increases the reputation of companies in the eyes of customers who want to acquire not only high -quality, but also environmentally friendly products.

Improving security standards

The main function of hatch covers is security for both pedestrians and vehicles. Innovations in this area include an improvement in anti -slip surfaces and increased constructive strength. Special coatings increase the clutch of shoes and tires with the surface of the hatch, preventing cases of falls and accidents. Also, thanks to new technologies, it is possible to create more reliable systems for fixing the lids to exclude their possible displacement, which is especially important on roads with intensive traffic.

Clients interaction and personalization of products

With the development of information technology, the lamp covers have the possibility of closer interaction with customers. The creation of personalized solutions for specific requests of the customer has become much easier. The possibility of choosing sizes, color solutions and even functions allows customers to receive products that ideally correspond to their expectations and operating conditions. This approach allows the plants not only to attract new customers, but also to maintain the loyalty of existing ones, offering them unique products of the highest quality.

Luke cover factoryadheres to the principles of innovative development, constantly improving its products taking into account the modern achievements of science and technology. This allows not only to meet the high requirements of the market, but also to set new standards in the production of industrial solutions.