OEM factories Round Luke covers

OEM factories Round Luke covers

Round lids of hatches are inconspicuous, but important elements of urban infrastructure. They hide underground communications, ensuring security and aesthetic appearance. The production of these seemingly simple parts is carried out by specialized factories operating on the principle of OEM (Original Equipment Manuapacturer - the original manufacturer of equipment). This means that they produce products by order of other companies, which then sell it under their brand.

Production technologies and materials

The production of round hatches covers is a complex technological process that requires accuracy and high quality materials. Depending on the purpose and place of installation, various materials are used: cast iron, steel, composite materials, plastic. Cast iron is traditionally considered the most durable and durable material that can withstand heavy loads. However, modern composite materials are increasingly used due to lightness, resistance to corrosion and the possibility of creating more aesthetic solutions. The production process includes casting, stamping, welding, surface treatment and painting. Modern plants use automated lines, which provides high performance and manufacturing accuracy.

Quality and standards

The quality of the round lug covers is a critical factor that affects the safety of people and the serviceability of underground utilities. Therefore, OEM plants strictly monitor compliance with all the necessary standards and technical requirements. This includes quality control of the materials used, the accuracy of the size and geometry of the lids, as well as tests for strength and resistance to external influences. Product certification is a prerequisite for entering the market. Regular quality control at all stages of production guarantees the reliability and durability of finished products.

Diversity and prospects

Round lids of hatches are not just functional elements. Modern manufacturers offer a wide selection of design solutions that allow them to harmoniously fit them into the environment. From classic cast -iron covers to modern models with decorative elements - diversity allows you to satisfy any requirements. The prospects for the development of the industry are associated with the use of new materials, an increase in production efficiency and the introduction of innovative technologies aimed at creating even stronger, durable and aesthetic hatches.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling products-

875x500x35 Anti-ibsidiary adjustable noise and waterproof hatch cover

875x500x35 Anti-ibsidiary adjustable noise and waterproof hatch cover -

700x800x120 Gate for the belt are square on the outside and round inside

700x800x120 Gate for the belt are square on the outside and round inside -

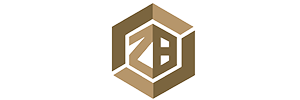

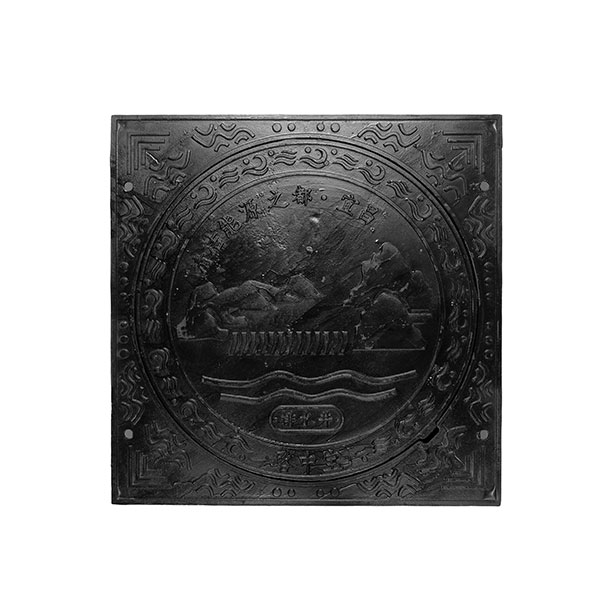

700 Composite Round Sazhoter

700 Composite Round Sazhoter -

400x600x60 Cast iron square lid

400x600x60 Cast iron square lid -

800x1000x120 Anti -corrosion surface aerosol paint stains a round hole

800x1000x120 Anti -corrosion surface aerosol paint stains a round hole -

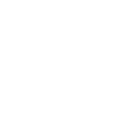

700x700x60 Cast iron square lid

700x700x60 Cast iron square lid -

750x1000x100 Composite round well

750x1000x100 Composite round well -

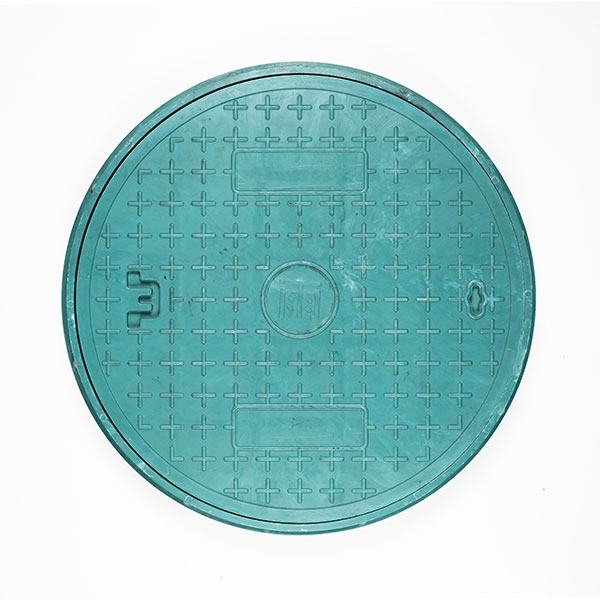

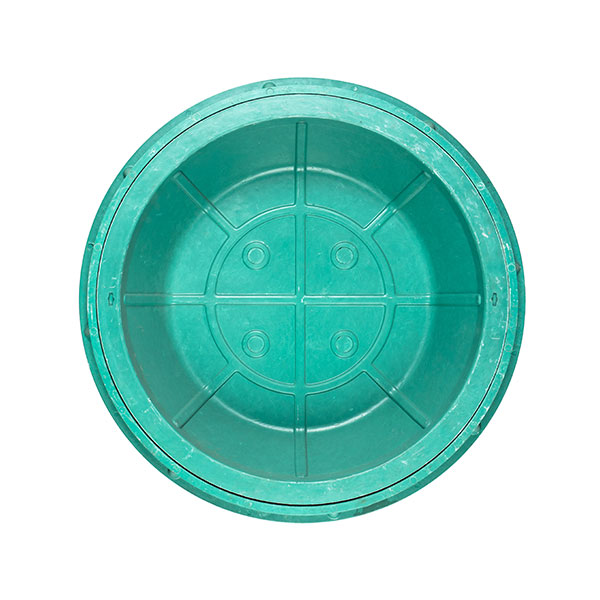

700x1050x60 square composite lid of a double opening hatch

700x1050x60 square composite lid of a double opening hatch -

700x900x150 Anti -deception cast -iron round well

700x900x150 Anti -deception cast -iron round well -

770x770x130 Composite square soother

770x770x130 Composite square soother -

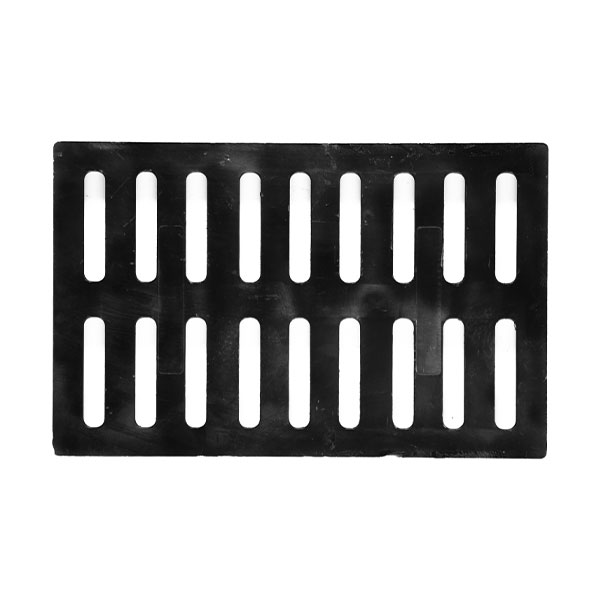

500x320x50 Composite mutual combuster with small teeth

500x320x50 Composite mutual combuster with small teeth -

700x760x50 Composite round well

700x760x50 Composite round well

Connectedsearch

Related search- China Factory Diameter of the Cloded Bader cover

- Leading buyers of concrete covers of hatches in China

- Chinese suppliers of concrete rings covers with hatches in China

- Cheap square plastic sewer hatch of suppliers

- Leading countries-buyers GOST cast-iron hatches of hatches in China

- Plastic sewer caps with a factory hatch in China

- The price of metal entrance gratings in China

- Cheap composite grilles suppliers

- Cheap nets of hatch lids against falling manufacturers

- Cheap price plastic drains