Cheap composite hatches of hatches the main countries-buyer

Cheap composite hatches of hatches: the main countries-buyer

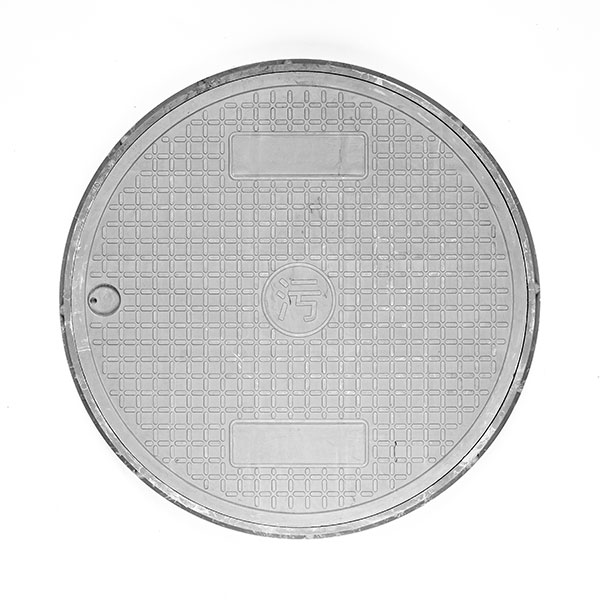

The composite hatches of hatches are becoming more and more popular all over the world due to their strength, durability and relatively low cost compared to traditional cast -iron analogues. This attracts buyers from various countries, especially those where the active construction of the infrastructure is carried out or the replacement of outdated sewage and water supply systems is required. But where is the main consumption of these inexpensive, but quality products concentrated?

1. Countries with a rapidly developing economy:

In countries with a dynamically growing economy, such as India, Indonesia, Vietnam and some African countries, the need to update infrastructure is colossal. The construction of new residential complexes, industrial zones and transport trunks requires a huge number of hatches covers. Composite materials here act as a profitable solution that can save the budget without prejudice to quality and safety. The price plays a decisive role, since the volume of procurement in these regions is very significant. Manufacturers of composite hatches of hatches are actively working on the adaptation of their products to local conditions and specific requirements.

2. Markets with an active infrastructure update program:

Even in countries with developed economies, such as some countries of Latin America and Eastern Europe, the problem of wear of old communications remains relevant. Replacing outdated cast -iron hatches of hatches with modern composite ones is an economically justified solution that allows you to improve road safety and extend the service life of underground networks. In these regions, when choosing suppliers, not only the price, but also quality, as well as the reliability of logistics chains, are often taken into account.

3. Regions with increased security requirements:

In regions with high seismic activity or prone to frequent natural disasters, the composite hatches of the hatches demonstrate their advantages in terms of lightness and strength. Their smaller weight compared to cast iron analogues reduces the risk of damage during earthquakes and other natural disasters. This, in turn, makes them an attractive option for public procurement in such regions, despite the fact that the price can be slightly above some other options in the market. Security in this case becomes a priority, which affects the choice of material.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling products-

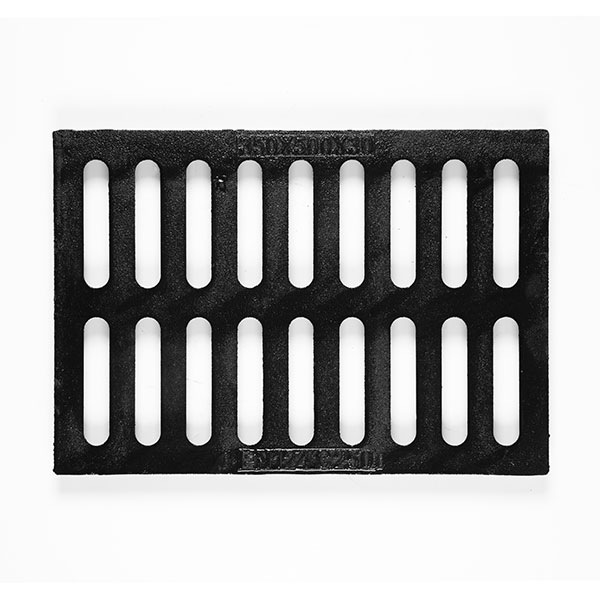

350x500x30 Cast iron -based combing with small teeth

350x500x30 Cast iron -based combing with small teeth -

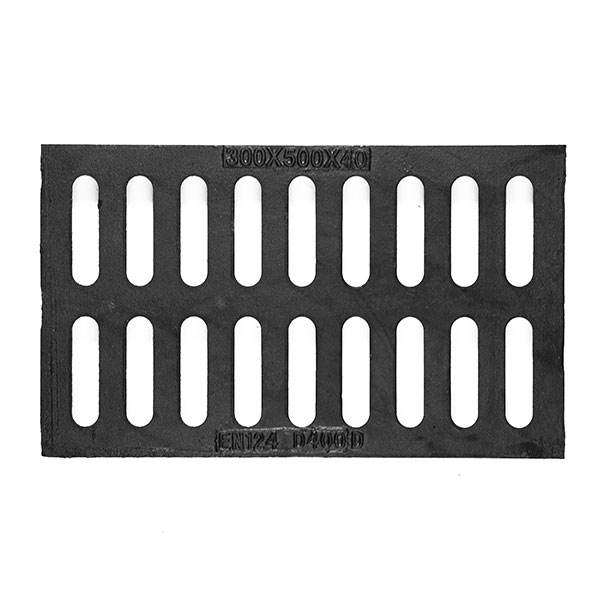

300x500x40 Cast iron mudfoiled comb with small teeth

300x500x40 Cast iron mudfoiled comb with small teeth -

450x750x40 Cast iron grill

450x750x40 Cast iron grill -

700x900x110 Round cast -iron well

700x900x110 Round cast -iron well -

700x370x60 Composite square lid of hatch

700x370x60 Composite square lid of hatch -

500x600x120 Anti -decay cast -iron round well

500x600x120 Anti -decay cast -iron round well -

500x500x45 cast -iron square lid hatch

500x500x45 cast -iron square lid hatch -

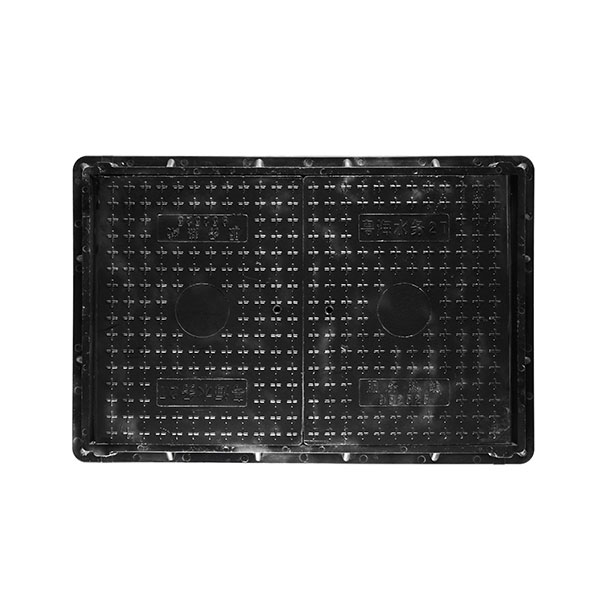

520x340x200 Composite water meter

520x340x200 Composite water meter -

700x1050x60 square composite lid of a double opening hatch

700x1050x60 square composite lid of a double opening hatch -

770x770x130 Composite square soother

770x770x130 Composite square soother -

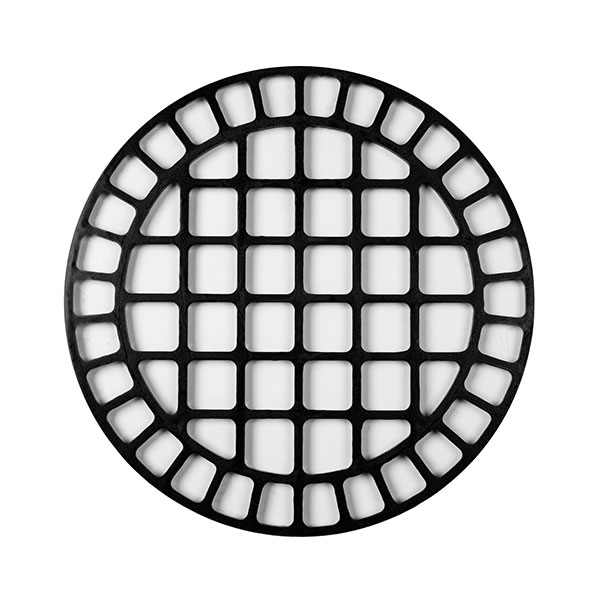

The mesh is against the fall

The mesh is against the fall -

Luke's artistic cast iron cover - matte

Luke's artistic cast iron cover - matte

Connectedsearch

Related search- Cheap composite high -speed hatches of hatches price

- Luke's cover is cast -iron

- Leading countries-buyers for the inlet grid DB 2 in China

- Cheap 400x400 inlet grids of suppliers

- China Cast iron lids t s250 prices

- Leading countries of the metal input grolboxes from China

- lid of the hatch of the well square

- Prices for water meters in China

- Looping iron cast iron anti-posting cover of the Luke of the Factory in China

- Chinese manufacturers of square hand covers