Products

-

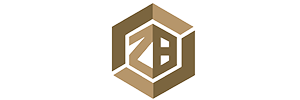

500x600x120 Anti -decay cast -iron round well

-

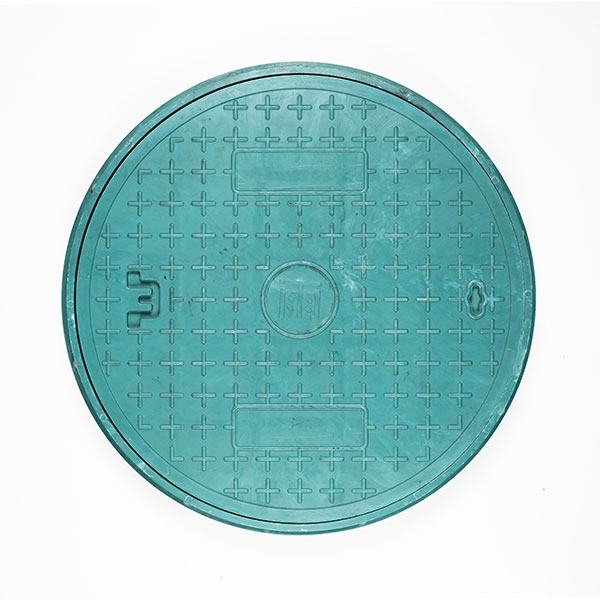

500x300x50 Composite square lid manhole

-

400x700x70 Composite grille

-

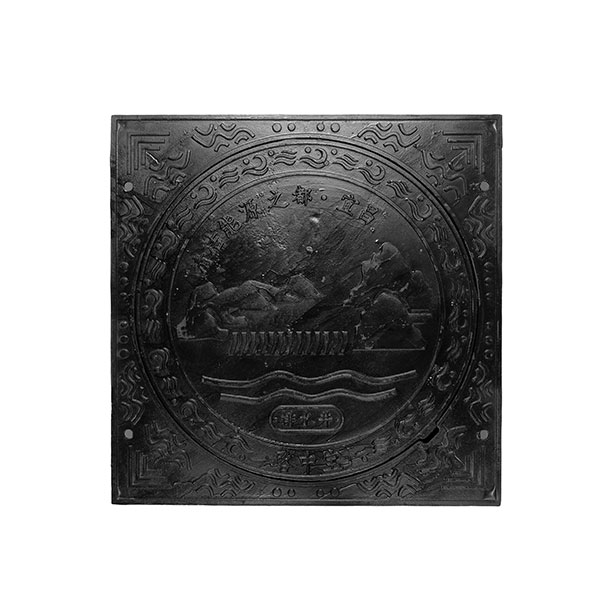

Artistic cast iron cover with copper coating

-

500x700x30 Composite high -speed cover

-

700x370x60 Composite square lid of hatch

-

Drainage tank

-

The mesh is against the fall

-

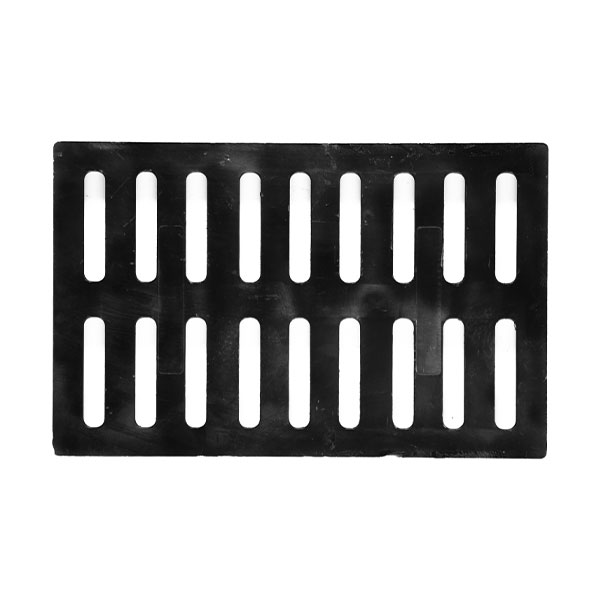

400x550x65 Composite grille

-

Cast iron round lugs to order

-

500x500x45 cast -iron square lid hatch

-

1200x740x60 Double cast -iron square well

-

520x340x200 Composite water meter

-

600 × 600 composite square planter

-

500x320x50 Composite mutual combuster with small teeth

-

620x1000x75 Composite square lid of hatch

Here is a professional translation of the text into Russian

Title: here is a professional translation of the text into Russian

Specification: 700*800

Carry the load: A15-E600

Description of the set of text: EN124

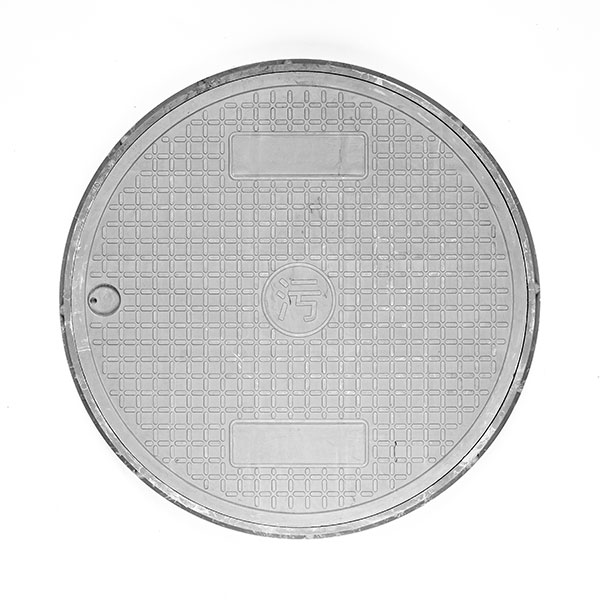

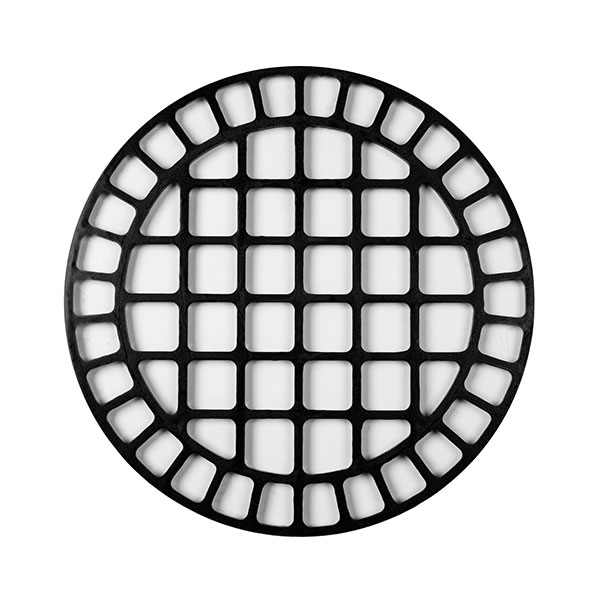

Text description: Cast iron water-free grille made of high-strength cast iron, made of high-strength cast iron QT500-7 by casting method. Specially developed for an effective drainage. The round design (standard diameter φ600-800 mm) in combination with an optimized scheme of grates' cracks is designed for zones with high runoff: roads, areas, parks. Key functions: rapid water removal, bearing the ability under load and protection against blockages. Corresponds to the standard EN124D400 (load 40 tons), is a key component of city drainage systems.

Description

marker

I. Why choose our grille from high -strength cast iron?

“Not every cast iron is a high -strength cast iron!”

Compared to gratings made of gray cast iron (high fragility, tendency to destroy) or composite plastics (rapid aging, low bearing capacity), QT500-7, due to the combination of strength and plasticity, provides a qualitative leap in compression strength, shock viscosity and durability, reducing the total cost of the life cycle by 40%!

II. Technical characteristics

1. Material and technology

- The basis of high -strength cast iron:

- Magnesium processing/rare earth elements provides spherical distribution of graphite.

- The strength of the strength at stretching ≥420 MPa, relative lengthening ≥10%, shock viscosity (≥12 J/cm²) significantly exceeds gray cast iron.

- density of 7.3 g/cm³, has no value for remelting, natural protection against theft.

- Anti -corrosion treatment:

- triple protection: zinc spraying (layer thickness ≥80 μm) + bitumen coating + sealing pores with epoxy resin.

-resistance to salt fog ≥2000 hours (ASTM B117), compatible with pH 4-12.

2. Hydrodynamic design design

- Vorthy crossbars of the gratings: radially located arc -shaped crossbars (clearance ≤15 mm) direct the flow of water to the center, increasing the efficiency of the drain by 40% (consumption ≥45 l/s · m²).

- Optimization against blockages: a gradient step of the crossbars (8 mm along the edges → 15 mm in the center) delayed large garbage, reducing the risk of blockages.

- Self -cleaning slope: the minimum angle of inclination of the grate surface (0.5 ° –1 °) allows rainwater to wash off silt, increasing the interservice interval by 50%.

III. Key advantages and features

① supervision, safety and stability

-Material: high-strength cast iron QT500-7, strength of ≥500 MPa, lengthening ≥7%, excellent shock viscosity.

- Load class: corresponds to the D400 class (load 40 tons), it was tested under heavy equipment.

- Design: a reinforcing mesh on the back of the side + anti -slip pattern (toothed/wave), friction coefficient in rain> 0.8.

② Highly effective drainage

- The area of open holes ≥23%: the optimized distribution of holes prevents the formation of a puddle.

- gratings ≤25 mm lattice: effectively delayed garbage, simplifies service.

③ Durable anti -corrosion protection

- coating: hot zinc (≥80 μm) + bitumen coating.

-resistance to atmospheric influences: stable from -30 ° C to +150 ° C; > 1000 hours of testing with salt fog without corrosion.

- Settlement service life: ≥30 years (under normal conditions).

④ Safety and ergonomics

- Protection against failing: optional internal stainless steel grid. steel 304 (load ≥100 kg).

- Anti -Vandal fixation: hidden loops/bolt locks reduce the risk of theft by 80%.

- Noise reduction: rubber gaskets eliminate the noise from the passage of transport.

IV. Areas of application

- Municipal construction: city highways, bicycle paths, drainage systems of green zones.

- Public objects: airports, ports, stations, large areas.

- Residential/commercial zones: LCD roads, entrances to parking lots, walking paths.

- Promzones: logistics parks, factory territories, warehouses.

V. Standards and certification

- International: EN124 D400 (load), ISO1083 (material).

- Chinese:

-GB/T 23858-2009 Lukes of viewing wells.

-CJ/T 327-2010 grilles for discharge of flip water.

- Certificates:

- SGS report on testing with salt fog (> 3000 hours).

- Recommended by the Association of Municipal Construction of China.

Resume

The cast-iron round water-free grille of high-strength cast iron changes the approach to urban drainage thanks to military bearing capacity, a 30-year-old unconscious service life and efficient management of storm waters. Key advantages:

1. The revolution in the drainage system: V-shaped direction of stream + self-cleaning exclude flooding with extreme sediments.

2. King of loads: a bearing capacity of 40 tons exceeds analogues.

3. Economic life cycle: 50% lower than service costs; The service life is 3 times more than gray cast iron.

This is an indispensable solution for protection against floods, transport hubs and high load zones, especially in conditions requiring uncompromising reliability and durability.